Project Description

Teardrop Glass at Private Offices/Conference Wall

PRIVATE OFFICE, VANCOUVER

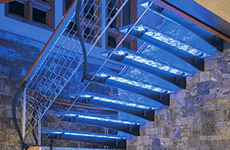

A stunning Architectural Glass conference room wall, using Nathan Allan’s exclusive Freeform Series Teardrop Glass. Kiln Formed Teardrop Glass provides more than adequate levels of opacity and privacy, while allowing ample streams of light to effectively brighten the office interiors. Both decoration and functionality come to life with Nathan Allan’s exclusive partition glass.

THE GLASS

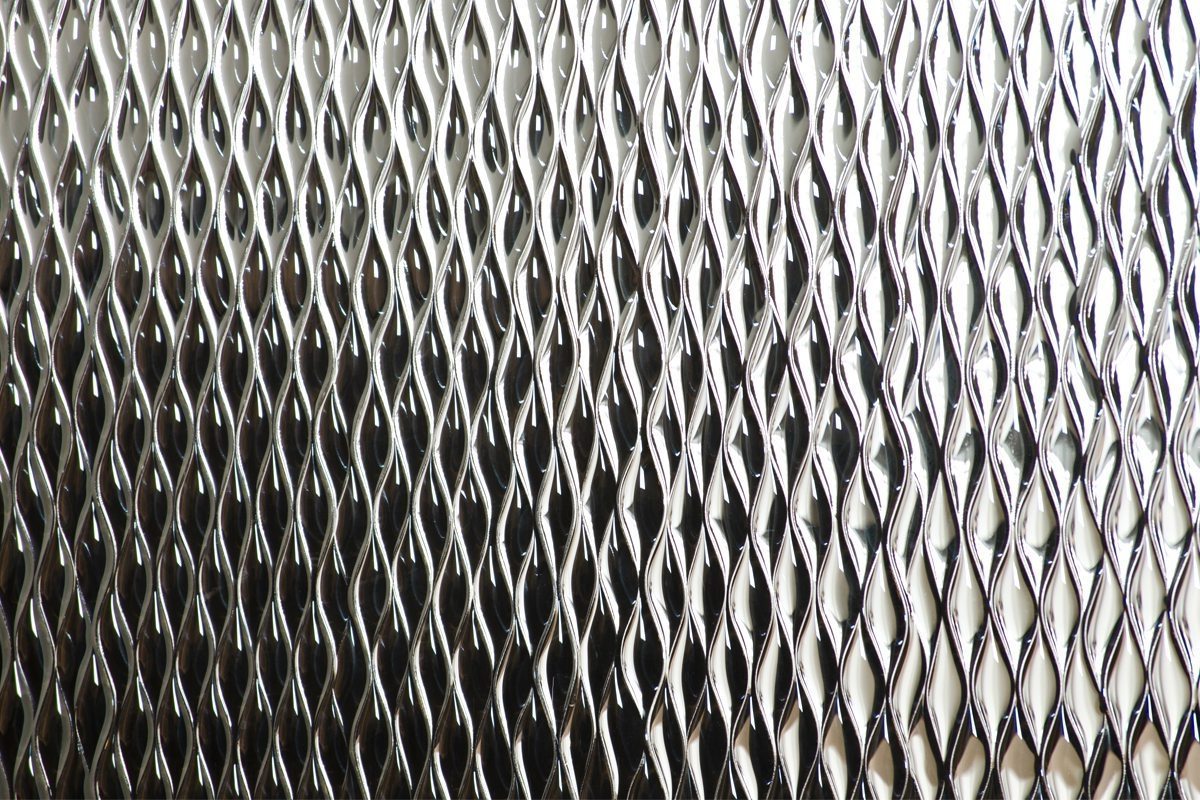

Teardrop Architectural Glass, part of Nathan Allan’s exclusive Freeform Series, is an exciting, new, and the first “texture less” kiln formed glass in our industry. Teardrop Glass is 95% clear, patterned glass, with only minimal shaping texture lines. With the 3D Convex shapes of each Teardrop, distortion opacity is created for any privacy concerns, while demonstrating an incredibly beautiful Architectural Glass finish. Teardrop Architectural Glass Wall.

Teardrop Architectural Glass Wall

SPECIFICATIONS

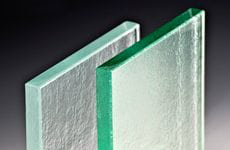

MM Exclusives specified a thick glass product to help provide a solid sound barrier. Using 1/2″ (12mm) thick, Low iron glass panels, provided the required barrier. Designing in 3’s, MaryAnn M of MM Exclusives divided the conference wall opening into 3 @ 3’6 x 8’6 panels. Polished edges allowed for easy installation for the local glazier, NA Technologies. Max panel sizes are available up to 6’0 x 11’0 (1800mm x 3350mm).

DESIGN

MaryAnn M, of MM Exclusives, desired to use a visually impressive Architectural Glass that was unique and different from other products in our industry. Teardrop Glass easily accomplishes the unique, but the glass also allows outside patrons to determine when co-workers are inside the conference room. This feature is part of the intent, as well as allowing large amounts of light to flow from both sides of the glass panels, through the “texture less” Teardrops.

INSTALLATION

Wood molding is installed on one side of the Conference Wall opening. NA Technologies glaziers place the Teardrop Glass panels on glass cushions along the bottom raised platform, inside the opening, and press the Teardrop Glass panels against the molding. While holding the glass panels upright, molding is tacked against the glass panels, on the opposite side, to hold the panels in place. Small, thin, beads (1/8” or 4mm) of clear silicone are injected between the vertical gaps in the glass panels and around the perimeter edges.